HS13BX Double Throw Rotary Type Knife Disconnect Switch

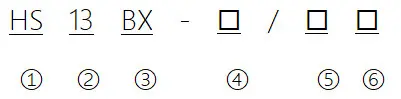

Type Designation

| 1 | Category Code: "HS": Double-throw Transfer Knife Switch |

| 2 | Design Code: "11": Central Handle Type "12": Side Front Lever Operation Mechanism Type "13": Central Lever Operation Mechanism Type "14": Side Handle Type |

| 3 | With "BX" indicates rotary operation type; Without "BX" indicates lever operation type |

| 4 | Conventional Free-air Thermal Current (A) |

| 5 | Number of Poles (1,2,3,4) |

| 6 | "0" indicates without arc extinguishing device; "1" indicates with arc extinguishing device |

Normal Working and Installation Conditions

1. Ambient air temperature not exceeding +40°C and not below -5°C.

2. Altitude at installation site not exceeding 2000m.

3. Humidity: Relative humidity of the air does not exceed 50% at a maximum temperature of +40°C, and a higher relative humidity is permissible at lower temperatures, e.g., up to 90% at 20°C. Special measures shall be taken against occasional condensation due to temperature changes.

4. Pollution degree of the surrounding environment: Level 3.

5. The switch shall be installed in a location free from significant shaking, impact, vibration, rain, and snow intrusion. The installation site shall also be free from explosive hazardous substances, and the environment shall contain no gases or dust capable of corroding metals or damaging insulation.

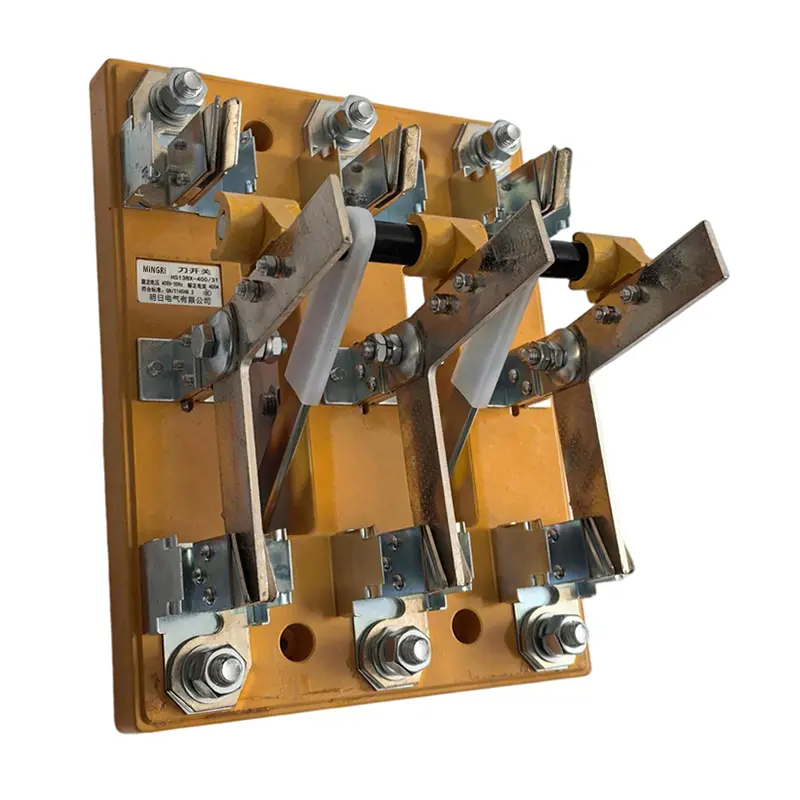

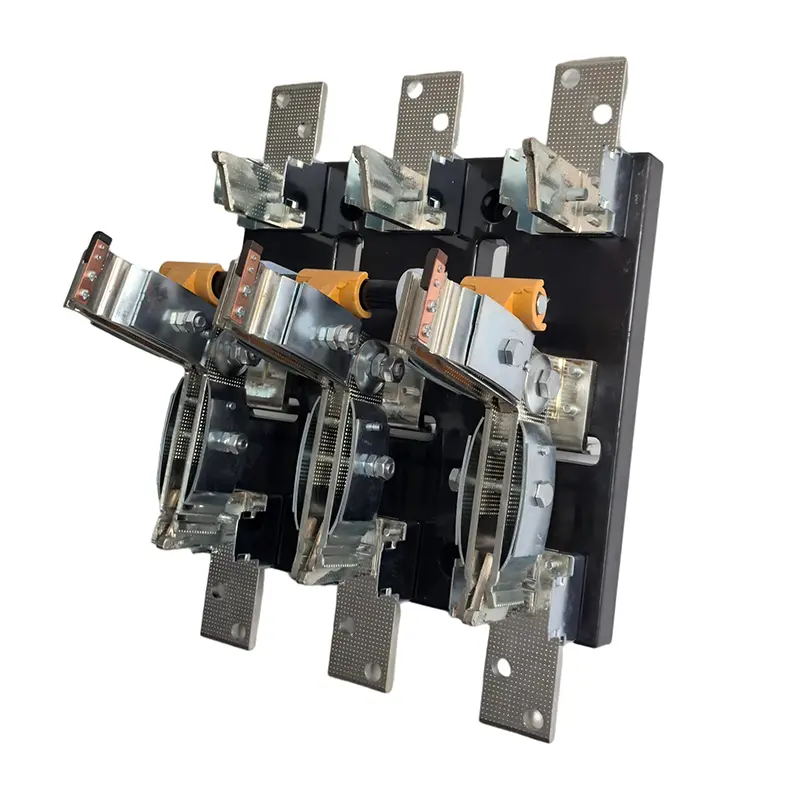

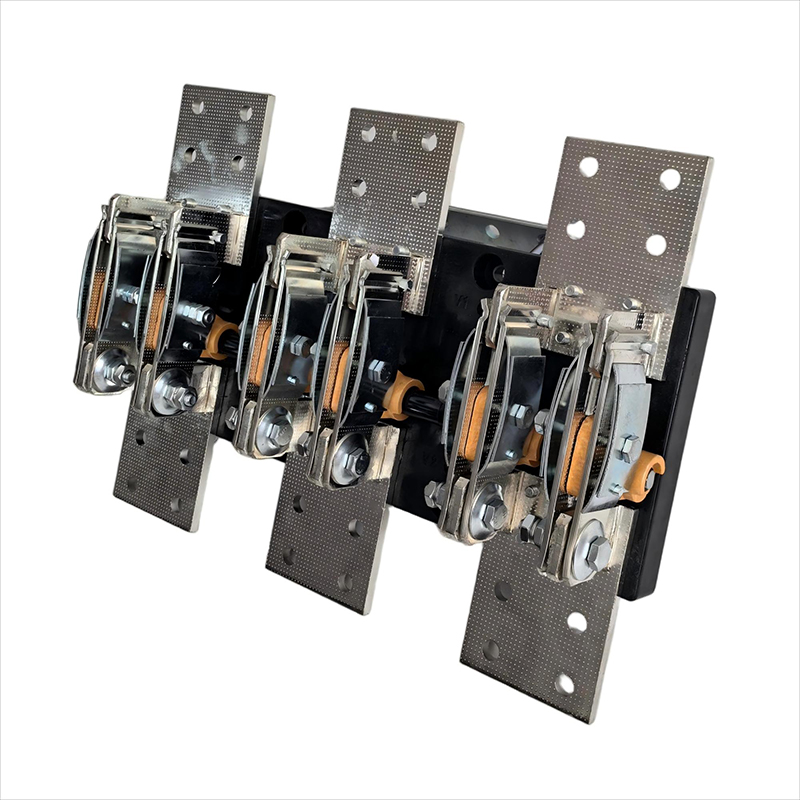

product Display

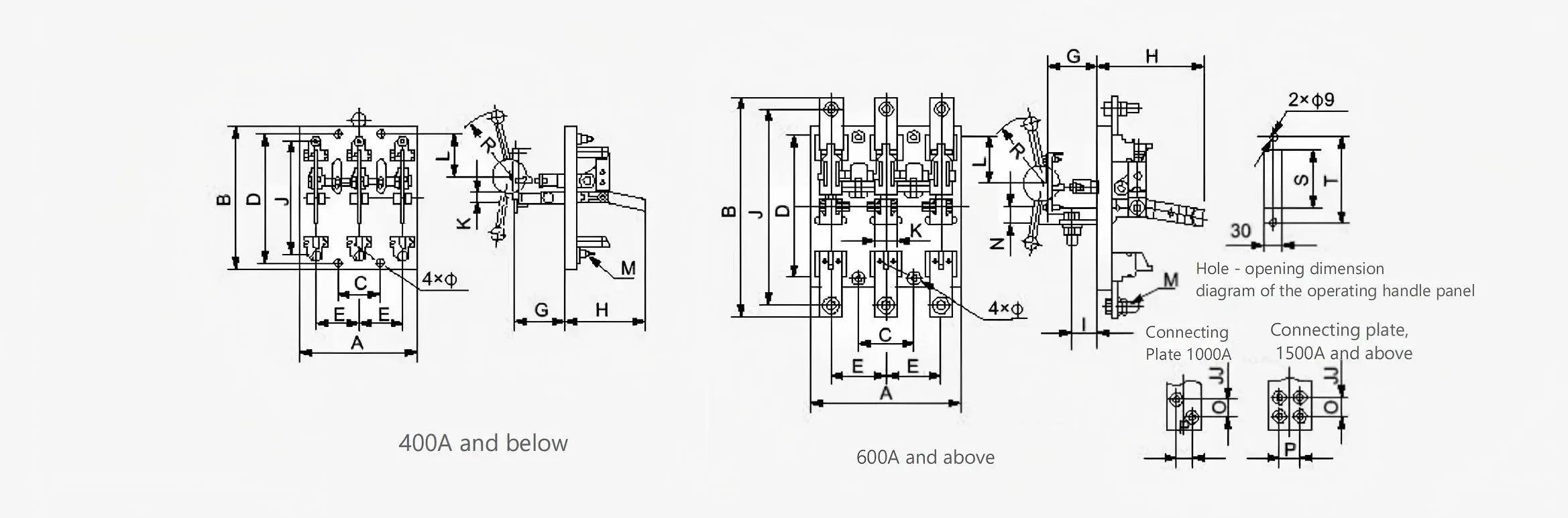

HS13BX Outline and Installation Dimensions

↓HS13 Central Lever Operation Mechanism Knife Switch Outline and Installation Dimensions, see table below.

| Model | Specification | 100A,200A | 400A | 600A | 1000A | ||||||||

| 2P | 3P | 4P | 2P | 3P | 4P | 2P | 3P | 4P | 2P | 3P | AP | ||

| HS13 Central Lever Operation Mechanism Knife Switch | A | 190 | 210 | 300 | 220 | 245 | 335 | 240 | 260 | 360 | 280 | 320 | 460 |

| B | 280 | 280 | 280 | 300 | 300 | 300 | 394 | 394 | 394 | 434 | 434 | 434 | |

| C | 160 | 80 | 160 | 180 | 90 | 180 | 200 | 100 | 200 | 240 | 120 | 240 | |

| D | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | 240 | |

| E | 80 | 80 | 80 | 90 | 90 | 90 | 100 | 100 | 100 | 120 | 120 | 120 | |

| G | 245~265 | 245~265 | 245~265 | 245~265 | |||||||||

| H | 160 | 160 | 160 | 185 | 185 | 185 | 190 | 190 | 190 | 235 | 235 | 235 | |

| I | 35 | 35 | 35 | 26 | 26 | 26 | 36 | 36 | 36 | 36 | 36 | 36 | |

| J | 210 | 210 | 210 | 256 | 256 | 256 | 354 | 354 | 354 | 358 | 358 | 358 | |

| K | - | - | - | - | - | - | 40 | 40 | 40 | 50 | 50 | 50 | |

| L | 75 | 75 | 75 | 70 | 70 | 70 | 70 | 70 | 70 | 60 | 60 | 60 | |

| N | - | - | - | - | - | - | 30 | 30 | 30 | 40 | 40 | 40 | |

| O | - | - | - | - | - | - | - | - | - | 25 | 25 | 25 | |

| P | - | - | - | - | - | - | - | - | - | 25 | 25 | 25 | |

| R | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 230 | 230 | 230 | |

| T | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| T | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | 146 | |

| M | 8 | 8 | 8 | 8 | 8 | 8 | 16 | 16 | 16 | 12 | 12 | 12 | |

| A | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 9 | 9 | 9 | 9 | 9 | |

| Model | Specification | 1500A | 2000A | 3000A(2500A) | ||||||

| 2P | 3P | 4P | 2P | 3P | 4P | 2P | 3P | 4P | ||

| HS13 Central Lever Operation Mechanism Knife Switch | A | 310 | 370 | 510 | 450 | 500 | 680 | 600 | 600 | 800 |

| B | 504 | 504 | 504 | 480 | 480 | 480 | 540 | 540 | 540 | |

| C | 260 | 130 | 260 | 180 | 180 | 360 | 200 | 200 | 400 | |

| D | 280 | 280 | 280 | 240 | 240 | 240 | 280 | 280 | 280 | |

| E | 130 | 130 | 130 | 180 | 180 | 180 | 200 | 200 | 200 | |

| G | 245~265 | 245~265 | 245~265 | |||||||

| H | 255 | 255 | 255 | 235 | 235 | 235 | 260 | 260 | 260 | |

| I | 32 | 32 | 32 | 48 | 48 | 48 | 50 | 50 | 50 | |

| J | 404 | 404 | 404 | 37 | 37 | 370 | 404 | 404 | 404 | |

| K | 70 | 70 | 70 | 100 | 100 | 100 | 120 | 120 | 120 | |

| L | 70 | 70 | 70 | 60 | 60 | 60 | 70 | 70 | 70 | |

| N | 46 | 46 | 46 | 50 | 50 | 50 | 50 | 50 | 50 | |

| O | 35 | 35 | 35 | 40 | 40 | 40 | 45 | 45 | 45 | |

| P | 35 | 35 | 35 | 55 | 55 | 55 | 68 | 68 | 68 | |

| R | 280 | 280 | 280 | 280 | 280 | 280 | 280 | 280 | 280 | |

| T | 130 | 130 | 130 | 130 | 130 | 130 | 140 | 140 | 140 | |

| T | 164 | 164 | 164 | 164 | 164 | 164 | 180 | 180 | 180 | |

| M | 12 | 12 | 12 | 12 | 12 | 12 | 16 | 16 | 16 | |

| A | 11 | 11 | 11 | 11 | 11 | 11 | 13 | 13 | 13 | |

Claire

Claire Mr.Fu

Mr.Fu

Claire

Claire