S13-M Type 10kV Series Hermetically Sealed Distribution Transformer

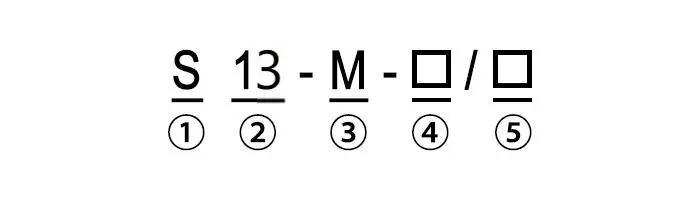

Type Designation

| 1 | Three-phase Oil-immersed Transformer |

| 2 | Performance Level Code |

| 3 | Sealed Construction |

| 4 | Rated Capacity kVA |

| 5 | Voltage Class kV |

Service Conditions

1.Maximum ambient temperature: +40°C

2.Minimum ambient temperature: -25°C

3.Altitude: <1000m

4.Maximum monthly average relative humidity: 90% (at 20°C)

5.Installation location: Installed indoors or outdoors at sites without fire or explosion hazards, severe contamination, chemical corrosion, and severe vibration.

product Display

Technical Parameters

| Rated capacity (KVA) |

Voltage Combination And Tap Range | Connection group label |

S13 | S11 | Short Circuit Impedance (%) |

||||

| High voltage (KV) |

Tapping Range Of Voltage % |

Low voltage (KV) |

No-load loss (KW) |

On-load loss (KW) |

No-load loss (KW) |

On-load loss (KW) |

|||

| 30 | 6 6.3 6.6 10 10.5 11 |

±5 ±2×2.5 |

0.4 | Dyn11 Yzn11 Yyn0 |

0.08 | 0.63/0.6 | 0.1 | 0.63/0.6 | 4.0 |

| 50 | 0.1 | 0.91/0.87 | 0.13 | 0.91/0.87 | |||||

| 63 | 0.11 | 1.09/1.04 | 0.15 | 1.09/1.04 | |||||

| 80 | 0.13 | 1.31/1.25 | 0.18 | 1.31/1.25 | |||||

| 100 | 0.15 | 1.58/1.5 | 0.2 | 1.58/1.5 | |||||

| 125 | 0.17 | 1.89/1.8 | 0.24 | 1.89/1.8 | |||||

| 160 | 0.2 | 2.31/2.2 | 0.28 | 2.31/2.2 | |||||

| 200 | 0.24 | 2.73/2.6 | 0.34 | 2.73/2.6 | |||||

| 250 | 0.29 | 3.2/3.05 | 0.4 | 3.2/305 | |||||

| 315 | 0.34 | 3.83/3.65 | 0.48 | 3.83/3.65 | |||||

| 400 | 0.41 | 4.52/4.3 | 0.57 | 4.52/4.3 | |||||

| 500 | 0.48 | 5.41/5.15 | 0.68 | 5.41/5.15 | |||||

| 630 | Dyn11 Yyn0 |

0.57 | 6.2 | 0.81 | 6.2 | 4.5 | |||

| 800 | 0.7 | 7.5 | 0.98 | 7.5 | |||||

| 1000 | 0.83 | 10.3 | 1.15 | 10.3 | |||||

| 1250 | 0.97 | 12 | 1.36 | 12 | |||||

| 1600 | 1.17 | 14.5 | 1.64 | 14.5 | |||||

| 2000 | 1.55 | 18.3 | 1.94 | 18.3 | 5.0 | ||||

| 2500 | 1.83 | 21.2 | 2.29 | 21.2 | |||||

Product Features

1.The transformer core is laminated from imported high-quality cold-rolled silicon steel sheets, significantly reducing no-load loss and no-load current. The core is also bound to ensure compactness and reduce noise.

2.The high and low-voltage windings are wound with oxygen-free copper. The low-voltage winding for 500 kVA and below employs a double-layer cylindrical structure, while for 630 kVA and above, it uses a double or quadruple spiral structure. The high-voltage winding utilizes a multi-layer cylindrical structure.

3.The transformer vector group is Dyn11, which reduces the impact of harmonics on the power grid and improves power supply quality.

4.The transformer features a fully sealed structure, extending its service life and eliminating the need for core lifting (internal inspection) and maintenance.

5.The measured noise level is lower than the standard requirement.

Claire

Claire Mr.Fu

Mr.Fu

Claire

Claire